Forming a SAM on a gold electrode

In this note we discuss the formation of a Self Assembled Monolayer (SAM) on a gold electrode. We discuss both the cleaning the electrode and then assembling the SAM.

At ZP we are contract developers and manufactures of biosensors, and so as we manufacture a biosensors through a several step process we like to test the sensor to ensure that the functionalization of the sensor/electrode is proceeding.

In the adjacent image we have tested our gold electrode with 10 mM ferrocyanide solution in 0.1 M KCl at 100 mV/s. In the adjacent figure you can see a gold electrode before and after cleaning with ethanol. One could interpret the fact that the two cyclic voltammograms (CVs) were very similar as indicating that the gold electrodes are very clean before cleaning, which is partly true, but at ZP we are experienced and would say that the ferrocyanide test is a diffusion test and not necessarily a surface condition test.

Though not the main focus of this note it is interesting that this study spanned over a weekend and so some sensors were stored dry and some were stored wet and so it is interesting to note that the electrodes were fairly stable when stored wet or dry, though our advice is to store dry.

In this study we were forming the SAM layer with octyl-thiol. At ZP we have some electrodes that are very resistant to organic solvent, whilst others that are not so resistant to organic solvent. The electrode used in this study is in fact a hybrid with the gold working electrode being very resistant to organic solvents whilst the other printed materials not being so resistant. This therefore influenced the way we applied the 1 mM octyl-thiol (OT) to the gold working electrode. We tried both dip coating the electrodes and spotting the solution on. When we dipped the electrodes the result was that we stripped the electrodes, whilst when we spotted the electrode we were able to keep the ethanol on the organic solvent resistant gold and not flood it onto the other electrodes. The difference can be seen on the adjacent image where the dipped electrodes have suffered damage from the solvent whilst in the spotted electrode the electrodes are pristine.

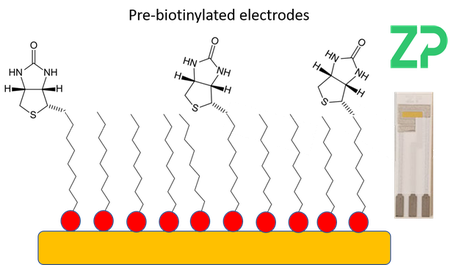

Note when wishing to have a biotinylated SAM, use a ratio of 1:4 biotinylated-OT:OT.

We functionalized for sensors with 20 microlitres of 1 mM octyl-thiol for 30 minutes, and we show see the CV signal before and after the SAM layer, it was clear to us that the ZP gold electrodes had several desirable properties:

- The working electrode was resistant to organic solvent – so it was possible to functionalise them without damaging the electrode

- The working electrodes are inherently reproducible – the bare electrodes give similar signals demonstrating that the electrodes are manufactured in a reproducible manner.

- The SAM formation is also consistent on these electrodes.

If we were to summarise how to form a SAM on a ZP electrode we would say ‘clean the electrode with ethanol, dry, and then apply 20 microlitres of a 1 mM solution of the thiol in an appropriate solvent for 30 minutes.

If you have read to the end of this note then we would strongly suggest contacting ZP as we are constantly updating and upgrading our technology so please contact us to find out the latest.

A short procedure

One of our ZP scientists recently helped a client with their efforts to make a SAM layer, below we have pasted the instructions they sent

1. Clean the electrodes dipping in H2SO4 (1M) for 3 minutes and then wash with a generous amount of DI water.

2. Pipette 2 µL of your diazonium salts with antibody and EDC/NHS solution onto the working electrode (WE) and let it incubate at RT for 1 hour. I believe this solution can be bought off-the-shelf.

3. Dip the sensors in 1% BSA, in PBS, for 1 hour and wash with PBS. The sensors should be ready to use.

4. For storage, please dip the sensors in 2% BSA, 2% Glucose, in DI for 1h and dry for 1h at RT. Remove excess solution before placing sensors in freezer. Before using the sensors stored in freezer please wash with PBS.

When testing the sensors, all electrodes should be covered with test solution and our advise is to use cyclic voltammetry technique available on the AnaPot.