Electroplating for Medical Devices

At Zimmer and Peacock we have a range of products and services on electroplating. At ZP we have a particular focus on the medical industry, but particularly medical devices. if you have any questions regarding electroplating for the medical devices industry please don't hesitate to contact ZP.

INTRODUCTION TO ELECTROPLATING FOR THE MEDICAL DEVICES INDUSTRY

There are two instrument that can be commonly used to perform electroplating, in the laboratory setting the potentiostat and at a larger scale a rectifier.

POTENTIOSTAT

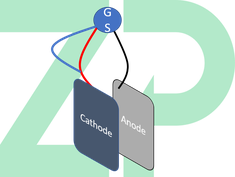

Using a potentiostat :

- Short the counter with the reference.

- Counter/Ref Electrode should be connected to the electrode to be modified (cathode)

- Working electrode should be connected to the sacrificial electrode (anode)

We control the current and the time and we observe the resulting potential

RECTIFIER

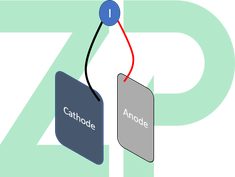

Using a current rectifier :

- Connect the sacrificial electrode to the Anode (usually red cable)

- Connect the electrode to be modified on the cathode (black cable)

- We control the current and the time and we observe the resulting potential

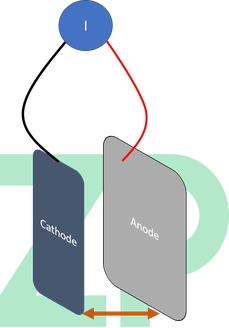

IMPORTANT PARAMETERS

- The distance between electrodes is an important parameter

- The electrodes should be parallel

- The anode (sacrificial) should be bigger than cathode

- The anode materials should be, ideally, the same of the deposited layer (sometimes stainless steel or Pt electrode could be used as general sacrificial anode)

CLEAN SURFACE

The ultimate aim of polishing and cleaning/activating is to make a water break free surface, as shown in the adjacent image. On the top half of the copper sheet, the surface isn’t completely clean and so the water is gathering up into droplets and staying on the surface of the metal. However, on the bottom half of the copper sheet the water has completely drained off the surface as it is completely clean and doesn’t provide anything for the water to cling to or gather around. This is a water break free surface and is ideal for effective electroplating. This should happen after you’ve completed the surface preparation step.