ZP is an ISO13485 contract developer and manufacturer of electrochemical biosensors.

As part of our technology platform ZP has the worlds largest range of screen printed electrodes intended for start-ups, entrepreneurs and academics whose ultimate goal is to make a commercially available sensor/biosensor.

On this page we discuss the issues with R and D screen printed electrodes.

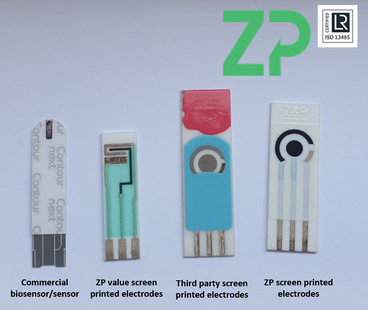

PROBLEM ONE, many screen printed electrodes are too big to be commercially viable at scale - A commercial biosensor like a glucose sensors has a distinct aspect ratio and overall size. A 'real' commercial biosensor often have widths of 7 mm or less and lengths that are 25 mm or less. This is because manufacturers know that manufacturing is more efficient higher the density/packing of screen printed electrodes.The issue is that many classical screen printed electrodes have widths of 10 mm and lengths of 30 mm. The ZP hyper value and value screen printed electrodes from Zimmer and Peacock have 60 % of the size of our more classic sized electrodes and so they can always be lower cost than their larger sized cousins, especially at a commercial scale.

PROBLEM TWO, many screen printed electrodes are not designed with microfluidics in mind- Zimmer and Peacock is the only company designing screen printed with the end application in mind. If you consider the value and hyper value screen printed electrodes from Zimmer and Peacock you will see that we have pre-formulated solutions for microfluidics.

PROBLEM THREE, wrong geometry - Zimmer and Peacock is the only company designing screen printed electrode geometries with how these assays will work in the final application. Many screen printed electrodes advertised to the R and D market are circular but if you examine a commercial biosensor they are often rectangular electrodes with the electrodes arranged perpendicular to the flow of sample. Though the 4 mm diameter electrode is popular in academia it does not work when thinking about designing a real product, see our article in 'Hacking a Glucose Sensor'.

PROBLEM FOUR, quality- Zimmer and Peacock is the only manufacturer of screen printed electrodes that is performing wafer mapping. Wafer mapping is a process by which screen printed electrodes are electrochemically tested before they are deemed of the required quality to be put into our stock and shipped to clients.

PROBLEM FIVE, commoditization of screen printed electrodes- The perception of screen printed electrode is that they are a commodity item that can be bought off the shelf and effortlessly integrated into a commercial application, during a research phase then electrodes can be bought from various vendors and tried out; but if truly commercializing using a screen printed electrode then a deeper engagement with the vendor needs to take place and a frame work agreement and/or supplier agreement put in place and probably commitments to monthly orders put in place.

PROBLEM SIX, viewing the screen printed electrode as a component in isolation of the system - One of the biggest errors by biosensor developers who incorporate screen printed electrodes in their sensing system is to think of the screen printed electrode as a component, and to asses the screen printed electrode in isolation of the entire system. At ZP we cannot take this isolation perspective of the screen printed electrode, what makes a sensing system is:

- Sample preparation - this is a big source of variability in any sensing system.

- Sample introduction to the sensor - how a sample is put onto a sensor or screen printed electrode can be a big source of variability in the raw signal

- Biosensing manufacture - At ZP we are world leading ISO13485 contract developers and manufacturers of electrochemical biosensors so we find the fabrication of reproducible biosensor formulations upon screen printed electrodes routine, but we see this as a significant struggle for many groups around the globe.

- Electrochemical excitation methodology - how well a screen printed electrode or biosensor will will work in a particular application is in part of course linked to the screen printed electrode, but getting the best out of a screen printed electrode or a biosensor built upon a screen printed electrode is intrinsically linked to the electrochemical method be it: impedance, voltammetry, amperometry, potentiometry etc.

- Calibration and signal extraction - This is often the least exploited aspect of the sensing system, and is as important as the screen printed electrode itself. The inevitable screen printed electrode inter and intra batch variability can be offset when the screen printed electrode, the electrochemical excitation and the signal extraction are viewed holistically.

- Hardware, app and Cloud - At ZP we have established the hardware, app platform and Cloud database that can accelerate screen printed electrode based applications to market; having developed the entire system for taking screen printed electrodes biosensors to market ZP has the perspective of how to take screen printed electrode systems to market.

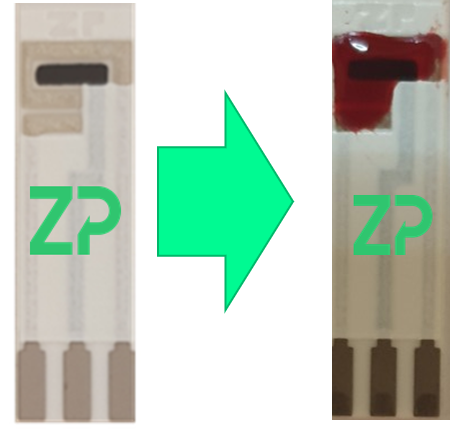

PROBLEM SEVEN - There are many applications where the sample itself is very precious, hard to obtain or expensive. The ZP electrodes are perfect as there size means that a sample as small as one drop of blood will cover the electrodes as illustrated in the adjacent image, where a drop of the authors blood has been used to cover all three electrodes of a carbon 303.

PROBLEM EIGHT - There is a lack of customer support and bioelectrochemistry expertise among the manufacturers of screen printed electrodes, at ZP we have over come this though our free questions and answers forum, click image to find out more.

RECOMMENDATIONS FROM ZP

At ZP our focus is different from other suppliers of screen printed electrode manufacturers as we are fixed on getting our clients and collaborators to market. This is why though we have the world's widest range of biosensors and screen printed electrodes we recommend our value gold 303, our platinum 303 and our carbon 303 electrodes, and our favorite screen printed electrode are our hyper value screen printed electrode.